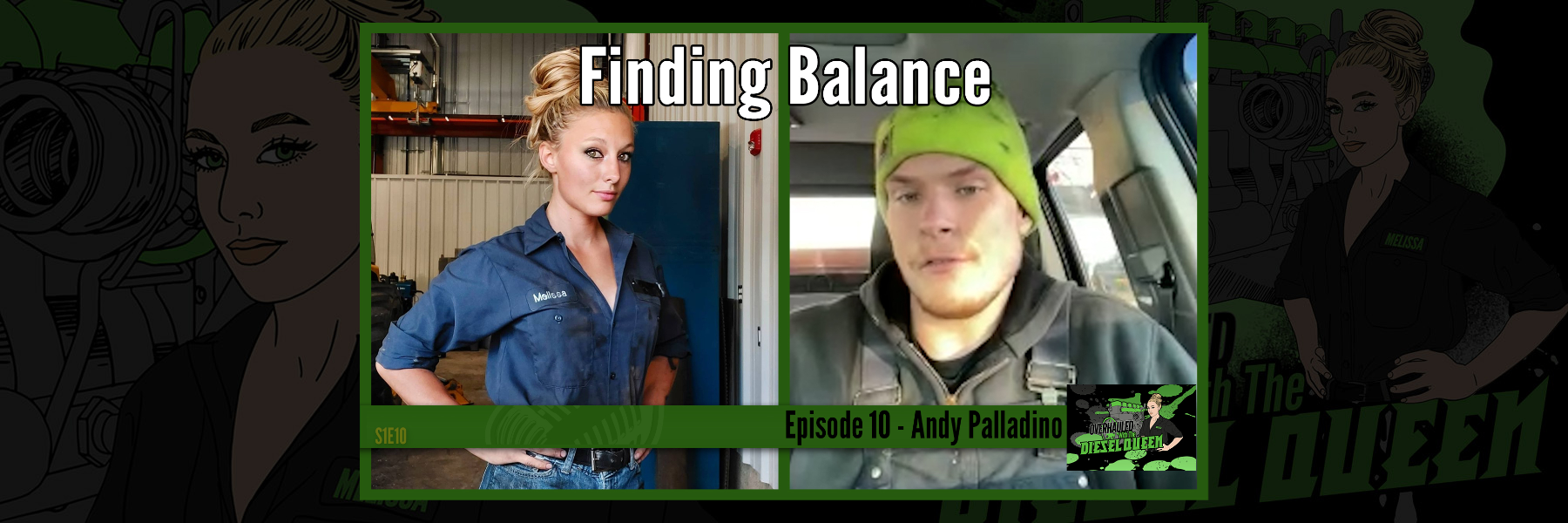

Finding Balance - Overhauled S1E10

Finding Balance - Overhauled S1E10 is now on your favorite podcast app!

Want to be a guest on Overhauled? - https://www.diesellaptops.com/pages/podcast-guests

In this podcast your host Melissa Petersmann (The Diesel Queen) discusses diesel technicians, trucks, the diesel economy at large, and many more interesting topics in a style that only she can bring - raw and unfiltered.

Melissa is joined today by Andy Palladino a Fleet Manager and Mechanic. They discuss the importance of work and life balance and how you can make your interests your career without letting it take over your entire life.

As always, thank you for watching and listening!

Connect with Guest:

LinkedIn - https://www.linkedin.com/in/andy-palladino-a658891a9/

Instagram - @petalspalladino

Transcript for Finding Balance - Overhauled S1E10

Speaker 1:

So we have a special promotion going on here in February. This is our diesel tablet. This was just launched last year. This is our mid-range diagnostic tool. It will do thousands of the most common diagnostic commands. So if you're working on your EGR system, you're trying to change engine parameters, you're trying to work on your SER system, this will do the resets, the calibrations, the installs, all the things. You can one tap to repair information to get instant repair information for all your fault codes. It's a great, great tool to put inside your shop and it's priced very, very aggressively for the price point.

In February, we have a special promotion going on. So if you buy this tool in February, and there's a limited amount, you will get five free online training courses. So these online training courses are not about the tool. These courses are about how to do electrical, how to troubleshoot after treatment systems, how to do all this advanced stuff that you need to know for today's commercial truck. So it's a $500 value, comes absolutely free with the product for the month of February. Check it out, 30 day money back guarantee. We know you're going to love it. We sold a ton of these things already.

Speaker 2:

Hey guys, welcome to Overhauled with the Diesel Queen. I am here today with Andy who is a fleet manager. Andy, would you like to introduce yourself?

Andy:

What's going on? My name's Andy. I'm from New Jersey and I currently work for a produce company here, and I take care of a fleet of over 35 trucks and try to do everything myself.

Speaker 2:

Yeah, so kind of give us a little bit. Part of what I do at this podcast is I try to dig into how people get into this industry, because for me people look at me like, oh my God, how did you get into the industry? It's like, actually if you look at my background it makes a lot of sense. So I try and dig into people's background, how they grew up, any kind of information like that, how you got into the industry, what made you decide to want to be in the industry. So if you want to kind of dig into your background a little bit as to how you got into this industry and why you chose this industry, that would be great.

Andy:

Sounds good. At a young age of 10, I started working for a race team here in New Jersey. We were based out of Waldwick, New Jersey and we raced all over the tri-state area, New Jersey, New York and Pennsylvania. Raced Northeast Dirt, big block modifieds and we run a bunch of races. I did that for about 12 years and then started working on stuff full-time, and more or less than what a hobby ... well, took a hobby and made it a career. So I started working at a car repair shop locally and then moved on from there. Started working at a truck shop in town that I'm from and unfortunately that got shut down, and now I'm here.

Speaker 2:

So I'm going to swing back to the race car comment. You said modified, so is that dragster modified stock or-

Andy:

Circle track.

Speaker 2:

Circle track, okay.

Andy:

Yeah, raced on dirt. They have a big block Chevy engine. Some have a small block Hemi engine.

Speaker 2:

That's where I was trying to make that connection, because I'm like, I thought they used Hemi... I was on the drag racing mode. So that's why I was just trying to clarify that.

Andy:

No one really went with the ... Dodge isn't really prominent in our area. All the circle track engines really come from GM. So in the drag racing world, the Hemi me is a different story, but not for going in circles.

Speaker 2:

I love all kinds of racing. I do have a soft spot for circle Track and I have a soft spot for drag racing. So when you said race cars, I'm like all right, we need to dive into that a little bit because I will never miss an opportunity to talk about race cars. So yeah, I will sit here and babble on for hours about drag racing. I have never missed, with the exception of this last year with all my moving, I have never missed the nationals. Well, I lived in Wyoming so I went to the Mile High Nationals for the drag racing strips and then we went to the Motocross nationals there. So I don't miss that ever for the world except for this year. So that was a sad day. Yeah, well Indianapolis apparently has a drag strip so that's going to happen next year hopefully. But so you said that you kind of started working at a car dealership and then you moved. What made you move from automotive to diesel?

Andy:

Well, when I started it wasn't a dealership. I was at a local small shop so it was just me and another guy there. Unfortunately, the money in my opinion just wasn't there for working on cars. So my dad's been a diesel mechanic for his whole life working on concrete trucks, and we always had food on the table and was always able to get whatever we needed to get. So I went to the whole truck side and I realized that, wow, I can go make $10 an hour more doing the same stuff, just working on a little bit heavier things. So I moved on to trucks, and I've been here ever since.

Speaker 2:

So I take it, regardless of the money, heavy duty is ... you like it better than automotive?

Andy:

Get more satisfaction out of the deal. You go home and you feel it more. You just weren't walking around all day. I don't know, I like it.

Speaker 2:

I never started on automotive. I went right into diesel. But I have obviously my own shit that I've worked on. I don't know if it's because it's just my own shit and it's maddening, and nothing ever works right when you're trying to work on your own shit, or if it's just the automotive in general, but I much prefer heavy duty than automotive.

Andy:

Got more room to work, more room to work. That's a big thing. Some of these places, some of these cars have shit all bound up and a whole bunch of swivels.

Speaker 2:

Plastic shit everywhere.

Andy:

Yeah, it's a pain in the ass.

Speaker 2:

Yeah, yeah. My boyfriend has a 2015 Challenger that I've done a little work on. Well, we've done a little work on and it's just stupid shit because he actually takes care of his stuff, so he doesn't really need that much work. But the plastic shit under the bumper and underneath the front of that car, oh my god. Fucking annoying. Fucking hate that shit.

Andy:

Flat off just to get to the drain plug.

Speaker 2:

I have not had to change his oil yet because he it's still under warranty and he has a maintenance plan on it. But I've done wheel speed sensors. He hit a raccoon, so I had to redneck, I'm going to use the term redneck up the bumper, like plastic shit under there. I had to kind of redneck that up so it didn't drag. We're going to be putting a wide body kit on it, so that's going to all get fixed eventually. But back to how, if you're a mechanic, you fix everybody else's shit and not your shit.

Andy:

Yeah, In my parking lot right now, I'm looking at my car over there that I haven't fixed in a year and a half. So just made me realize like, got to do that.

Speaker 2:

Yeah, that's story of my life. I have five trucks and two of them run, one of which my father has, and the other one is that Silver Dooley I have. Everything else doesn't run and major problems doesn't run. My maroon truck that I had for so long lost wrist pin and cylinder six. Long story short, kids don't buy eBay rebuild kits. I don't care if it says mall pistons. I don't care if it says mall pistons. I don't care what it says. If it does not have Cummins stamped on the parts, don't buy it. Every seal in that motherfucker leaked, every single one of them. I've had to replace every single seal I put on that engine. I rebuilt that engine like 80,000 miles ago. I had to put new seals in everything, and you replace it with an OEM seal and it's fine. It's good.

It's like, what the fuck guys. Then I learned actually two weeks before I was supposed to move be Indiana, my wrist pin ... well, I started hearing like a knock, and at first it was a little quiet, so I wasn't quite sure. It almost sounded a little top [inaudible 00:09:02]. It definitely wasn't rod bearings. I knew that it definitely wasn't a main or a rod bearing, and it was a little bit of a knock. I thought it was a fuel knock. Well, I knew better but I was praying in my heart it was just a fuel knock. I did the temp tests on the exhaust manifolds and I found one cylinder that is actually number three that was not warming up the same as the rest. I've had tons of issues with the aftermarket fuel injectors I've put in that truck when I rebuilt it.

So I'm like, well it's probably the body again, and I'm going to have to fix that. So I went through and did all that and fixed that one fuel injector and it still knocked. I knew better when I pulled that valve cover off and there were little tiny sparkles and the oil on the top of the rockers, I knew I was in trouble, but I was still praying that I was wrong because, well I'm retarded. But long story short, I lost a wrist pin in cylinder six and I red necked that engine up high enough to get the oil pan off, and looked up in there and cylinder six is scored to fuck.

If you take that piston, you put it all the way down towards the bottom, you can sit there and pry it in the cylinder wall with the pry bar. At first I'm like, well I know this is not normal but I'm just going to double check for my sanity. I went and pry it on number one because they're both down at the same time, and tight as shit. The other one's [inaudible 00:10:34] loose. So I'm like yep, that's fucked.

Andy:

That's why you mentioned you kind of had the engine all jacked up. I was doing an oil panel on a six seven Cummins once and had forklift holding the engine up. It was like a Friday at 4:30 or something. I get up from underneath it to go to the other side and I nail my forehead on the forks. Oh my God, I bled. I was like opening a can, so bad.

Speaker 2:

Been there. I've done a lot of backhoe transmissions for John Deere and, when you do backhoe transmissions for John Deere, you raise it. It looks really stupid, but you raise it all the way up in the air as high as the outriggers will put you, sometimes higher. Sometimes you have to use a boom on the backhoe to push it higher. Then as high as you got to tip the bucket up and push down. So you pick this motherfucker up to where you can almost walk underneath it. I can't tell you how many times I've come out underneath one of them backhoes trying to do a transmission and I nailed the middle of my back on the fuel tank corner. It never fails, or the steps. So yeah, we've lost a couple brain cells, right? For reasons.

Andy:

[inaudible 00:11:50] inhalation, minor concussions I guess.

Speaker 2:

So yeah, I've got my maroon truck that is fucked and needs another engine. It's actually sitting in my shop. I bought another truck to move out here. That's where the silver Dooley came from. Bought that, hauled that piece of shit and all my toolboxes out here, on my dirt bikes. That maroon truck has sat ever since. Now it's become the horrible, horrible habit of all mechanics as it's not a parts truck and that's not what it's there for, but I've been robbing parts off of it because well it's there and it's convenient. So that's fun.

I also have a third gen that's in paint that's actually still in Wyoming and the engine's here, so that's also cool. My dad had that and he dropped the valve and the head is jumped, so that's cool. But I got sidetracked by my project cars. I could sit here and talk about my problems with my project trucks all day. Yeah, that's a part of I guess owning 20 year old trucks, but at least I own my trucks. So I guess there's that. So the fleet that you run right now, is that a particular brand of vehicle?

Andy:

We have all freight liners and then-

Speaker 2:

Oh I'm sorry.

Andy:

Yeah, I know, but it's easy to get parts for, easy to work on so it's nice. But then we also have a few [inaudible 00:13:30]. We have a couple 389s that go from Florida all the way up to Boston twice a week. So always chasing the East Coast, running those. Hopefully they're all brand new, so really no problems with breakdowns yet.

Speaker 2:

Coming from a mechanic that has been privileged, if you would like to call it, growing up in dealerships, what is some of the challenges that you face running a fleet? Obviously, that it's not a dealership backing.

Andy:

Luckily there's enough information out there that you can get by without having dealer backing. The parts places is right down the road, so luckily I don't need to travel too far for that.

Speaker 2:

Did you guys have a bunch of issues with parts over the last couple years?

Andy:

Over the last couple years we have, yeah, definitely more so with the reefer unit side. So I also take care of all the reefers that our trucks have.

Speaker 2:

So you're not just a fleet of trucks. You got guys got trailers you're taken care of too.

Andy:

Yeah, trailers and box trucks that have reefer units on it as well.

Speaker 2:

Okay. I was curious about the part situation because we ran into, especially during COVID, was like we couldn't get fuel filters to save our-

Andy:

Fuel filters. I couldn't get belts. The simplest of things were unavailable, and that kind of put me in a hard place because, unfortunately without the reefer unit running, the trucks no good either. So I have trailers sitting waiting for parts and I have trucks sitting waiting for parts, and they're both good trucks and good trailers but just have no reefer unit.

Speaker 2:

So you ended up ... did your family own this race car business or was involved in this race car business when you were younger?

Andy:

It was in my family. They grew into become my second family. But my dad worked with him for a little while back in the early nineties and then I went one Saturday and the driver Tom, he asked me if I wanted to help him wash the car the next morning. I was 10, so I was ecstatic to be able to go power wash a dirty race car. It was kind of history ever since I was there. We worked every Tuesday and Thursday night and then we raced Saturday, and then we washed on Sunday. Then a couple years later, we started racing two nights a week. So it was kind of every night after school I'm going to the shop and we're building race cars. So ended up being a lot of work and almost just like a full-time job, but it was all volunteer, I guess you could say. It was all for fun.

Speaker 2:

Well, when you're a kid it's a race car. It's like, yeah freely. I would probably help right now for free on a race team if I could.

Andy:

Such a great environment. You can really bring anyone there and you don't need to worry about ... I don't know, everyone's just super nice no matter who it is. Everyone has the right mindset. Everyone's happy, everyone's there to have fun.

Speaker 2:

Yeah, I'm sure that's a little bit different than the NHRA Pro Drag series. Those guys are all super serious all the time.

Andy:

Yeah, but the hospitality side of that, you can go sit ... If you choose to sponsor a car, they'll sit you right next to their pit area and you can go watch the guys work and tear down engines from a block to a full running complete engine in a half an hour.

Speaker 2:

Yeah.

Andy:

That's a cool part about going to those races.

Speaker 2:

I remember the first year that I went to the NHRA Mile High Nationals, there's like a guy that, in between the races ... I don't remember which sets he was in between, but there's a guy that stood up in the pits and he was talking about dragsters in specific, but funny cars dragsters, the top fuel side of it. He said something that was very interesting and, as a mechanic, this really piqued my interest. Part of the reason they don't bolt the heads down until five minutes before they're supposed to race is because the thickness of the head gasket changes. They put different thicknesses of head gaskets in there depending on ... they've got an 8,000 thing lists of what they use to calculate the head gasket thickness. But I found that really interesting.

Andy:

Yeah, because that could be either you're going down the track that you're going to be lit up the whole way or you're going to be blowing up halfway down and up losing the race.

Speaker 2:

Yep.

Andy:

Yeah, stuff's crazy. I have a lot of appreciation for the tuners and stuff that put the time and effort into that.

Speaker 2:

Oh yeah. Well, the Mile High Nationals is a big deal because obviously out of the name, it's Denver, Colorado, so it's a mile high. I believe that's one of the highest elevation racetracks they have. So that's kind of cool. So when you went to high school and you were in high school, did they have any welding classes or automotive classes that you took? Nothing?

Andy:

No, I had absolutely nothing. I couldn't even go to home ec and learn how to cook. I didn't have anything.

Speaker 2:

Seriously?

Andy:

Yeah, I had nothing. My school, I graduated with 84 kids. School probably only had 500 kids in it. Yeah, we didn't have anything like that, not even a wood shop. It sucked.

Speaker 2:

Damn. That's an interesting ... that actually is a good point because part of what I tell people all the time or what I relay in this podcast is I was very fortunate. Even though I grew up around this stuff and my father was a logger, everybody's heard that story before. I grew up around the shit. My high school and my middle school, even middle school, the last year of middle school you could take welding. So I literally could take welding and automotive and ag mechanics and agriculture classes and everything all the way through the end of middle school all the way through high school. What I've told a lot of people is Laramie, Wyoming is just where I graduated from. They made it mandatory that you had to take at least one of either welding or woodworking. You had to take one semester of that. Then you also had to take at least one semester of automotive. So that was a requirement to graduate.

So there's a lot of kids that ... For me, I was exposed to it anyways, but there's a lot of kids that had never been exposed to anything like that before that got exposure to those type of industries through high school. I think that's, as you know because your high school is a perfect example of not having any of those classes, a lot of high schools are getting rid of those electives, and I think that's hurting the kids that are entering this industry because part of visa laptops thing with this is how can we get more people into the industry?

People like you and me make sense. We grew up around it. Obviously it makes sense as to why we got in there, but how can we get more kids and more people in there? That's why I always ask people, does your high school have classes, trade classes and stuff, because I really think that's where we're failing our youth. We are failing our youth in high school, in middle school. Going to high schools and putting on a big speech works for maybe two kids out of that entire high school.

Andy:

Two kids that can pay attention, because kids hate going school. Imagine you can go for half the day, you can go work on cars or learn how to weld or work on make wood things, and make going to school a lot more enjoyable.

Speaker 2:

Well, and make it a requirement so kids that would not ever normally pick those classes have the exposure. Yeah, okay, maybe don't make them take four years of it, but expose them to at least a semester of it. Because I've told the story a million times, that there was the little emo girl in my class, little goth emo girl in my welding class running welding beads. She was straight up like tall boots, fish net, bright white hair, black eye shot, straight up goth girl welding, running an arc welder. Do you think she would've picked that class if she wasn't a requirement? No. But she's pretty good actually. But that's where I'm like, no, I don't think so. Yeah, it gives her the chance. She would've never known. She would've never picked that. There was probably, for being honest, even in Laramie, Wyoming, which is a much different culture than most of the country, even in that area, there was probably only maybe 20% of the kids that went through those classes that ended up in a trade.

But I feel like that's higher. At least that's getting exposure and getting kids into it because welding is really fun. Before I wanted to be a mechanic, my first class I did at the end of middle school for welding, it was in Walden, Colorado. They had us running arc welders and a torch, a settling torch. Those were the two skills we learned. I came home after the first day that I got to weld and I told my dad I was going to be a welder, and I stuck with that plan until, I don't know, for a year maybe. But I think it's really important to get kids exposed to that stuff because the trades are ... it's not just a shit job anymore that you get paid shit money and it's just a dead end job.

These are careers that you can make a lot of money in and you can excel and you can grow pretty rapidly, especially nowadays because no one can find help, which is another thing I want to talk to you about. Do you guys have ... which I'm pretty sure I already know the answer to this. Do you guys have a tech shortage in your shop?

Andy:

It's just me. So if I wanted to bring on someone else, I could. Although finding someone is probably next to near impossible. So I guess I don't really have to deal with a tech shortage problem.

Speaker 2:

Do you have too much work? Is your workload-

Andy:

Yeah, I have a heavy workload, but it's definitely seasonal too. So we run a lot harder in the summertime than we do in the winter. So I kind of get to catch up on all the stuff that I missed on during the summer, in the winter and then all over again.

Speaker 2:

So you mentioned that hiring a tech is damn near impossible, if you were wanting to hire another tech, and that's the reality of this entire industry. When I was first figuring out that I was going to move to Indiana, I wasn't really sure where I was moving to. I wasn't really sure what area I was moving to. So I called around a couple dealerships in all parts of Indiana and I had three job offers, sight unseen. So obviously they were John Deere dealerships, right? Because that's my specialty and it just blew my mind that they could commit to hiring or wanting to hire somebody sight unseen. But they needed people so badly that they wanted to hire immediately. I don't know how it is in your area, but it sounds like you guys are just as bad with the tech shortages. Someone you could probably walk into anywhere and get a job.

Andy:

Oh yeah. Everywhere I go pick up parts from everyone has a sign, experienced techs needed, at any level. I go from north Jersey to South Jersey, picking up parts sometimes and there's signs on everyone's shop, everyone's door that they need to find techs. They're paying good money too. I don't know.

Speaker 2:

Yep.

Andy:

I don't know. It's pretty crazy how they can't fill the seats. But I think there's definitely could be some improvements in the work life balance aspect of it.

Speaker 2:

I agree with that. Expand on that a little bit.

Andy:

I'd like to see ... I feel like a lot of these shops, you could do a four-day work week.

Speaker 2:

Like four tens.

Andy:

And alternate. Yeah, do four tens or four twelves, whatever. I think that would be a big difference. It would make a lot more people interested in being a tech because I see ... A lot of the general contractors in the area, like the carpenters and the plumbers, they work like seven to 3:30 and then they're done. But a lot of the mechanic shops there, you're there at 6:30 and you're not leaving until six o'clock at night sometimes. So there's a 12-hour day and you can really make the same money being a carpenter or a plumber, at least in this area. So I guess people would lean to not being a tech because of the extent of the hours. Although you're getting paid for the hours, sometimes it's not really about the money. It's about having the time.

Speaker 2:

Exactly. I agree with that because you can make killer money if you're working overtime in this industry. I know techs that make a well over a hundred grand a year, but they have no home life. That's what I actually struggled with the last dealership I worked at is I could not get into ... well, I could get into the construction dealership that was close by, but they had some contingencies about my social media that was ridiculous. So I decided to look into the ag dealerships because I know I can work on ag equipment. I've worked on ag equipment before. It's not my specialty, but I can do it. Every single ag dealership is open almost a full day on Saturdays, if not a full day on Saturdays. And most of them are mandatory Saturdays. I found one dealership that I'm like, Hey, I'm not going to do this full every single Saturday being here till three o'clock or five o'clock.

I'm not doing that. That's stupid. So I told him, "If you need me, you guys already have some form of a rotation going on, so let's make a deal here." They told me, they're like, "All right, well instead of working every other Saturday you can work every third Saturday because honestly it's a skeleton crew anyways. There's a lot of people that don't show up anyways, so that's fine." Well, that went to shit like immediately and I worked pretty much every single Saturday. That's something that I think is really important too. All these companies are bitching about not having mechanics. I can't find mechanics, can't find people to work for me. It's like yeah, you're working six to eight weeks.

Andy:

Yeah, no one wants to do that, unfortunately. Listen, I'm all for going out and making as much money as you can, but there's also, I got two dogs at home and I want to hang out with them. Turning wrenches, although it's part of my life, it's not my entire life.

Speaker 2:

Well you work to live, right? You don't live the work. That's something that I really think ... It's hard for companies because I understand. I ran a shop or I helped. I pretty much ... well, I helped run the shop until my boss quit and then I ran the shop for three months. Before that, I helped him run the shop for a year. I learned a lot and I've understood a lot about ... it's hard. As a boss and as a company, it is hard because the workload doesn't slow down just because you can't find techs. Months stacks up months. I worked at one dealership prior to that, that was four months out of work. So if your piece of equipment needed to go into the shop, it was four months before you could get your piece of equipment into the shop.

That shop had 20 mechanics and they were still that far behind. So the quality of the mechanics were not that great, which is part of that problem, but besides the point. I learned a lot about how hard it is to balance that of yeah, my techs want to go home and they want to be home. I want to be home. I get it, I don't want to be here. But we got customers breathing down our necks, and we got a workload ... At that point, we were a new shop. We're trying to make a name for ourselves, we're trying to have a good reputation. It's hard. So it's kind of this tipping point in the industry right now where, if the companies don't start doing something about the work-life balance of their technicians and kind of catering ... Obviously there's always that one guy in the shop that wants to work 80 hours a week and he never wants to be home.

Fine, let him do it. Fuck it. If he wants to do that, great, go for it. I used to be that way when I was in the industry. The first two years I was in the industry, I got as many hours as I could on my paychecks, and if I could get over 120 hours on a paycheck, I was proud of that. If people want to do that, then fine, great. But there's going to have to be a change. It's like work-life balance thing. If they want to be able to drop their workload enough to not need to work their mechanics like 14-hour days, they're going to need to drop ... They're going to have to stop working their mechanics 14 hours a day because nobody wants to come to a shop and work 14 hours a day.

I think we could entice a lot more people into this industry if you're like, Hey, yeah, you're working eight or 10 hours a day. I feel like that's reasonable. Eight, 10 hours, that's reasonable. Four tens, even four twelves. I work four twelves if we're supposed to be on overtime, give them some options to help. If you're going to be working me like a dog and I'm going to be here for 12 hours a day, give me a three-day weekend. Or fuck, most of these shots, give me a two day weekend that I don't have to argue about.

Andy:

Got to deal with that. I don't know. I could never do ... I could, but I'm just saying I wouldn't choose to work six days a week. That's not my thing.

Speaker 2:

Even the half days, it's stupid.

Andy:

Yeah, because what are you going to get done?

Speaker 2:

Oh you don't. No one gets anything done on Saturday. There isn't a point

Andy:

Because you think about, oh well yeah we're open on Saturdays, but you're not actually doing shit on Saturdays, so are you really even open?

Speaker 2:

Agreed. Well, and the same concept goes to working I feel like anything over 10 hours a day, most people are pretty good for eight hours. Most people can work six to eight hours solid. But if you're working over 10 hours, those last couple hours or anytime after nine or 10 hours, people are useless. No one's getting shit done. Everybody is just waiting for the clock to take over so they can go home. I think shops are much more productive when they're not trying to work that much overtime because it's the same concept as Saturdays. Ain't nobody to get anything done. We've all worked in shops. Nobody gets anything done. Everybody's sitting on their computer at the end of the day.

Andy:

Maybe we shouldn't tell everyone that so some people can still enjoy their fucking off on Saturday days.

Speaker 2:

Well the bosses know it, right? Because it's not the foremen that are making those rules. It's the people above them that have no idea what's going on in the shop. But yeah, that was definitely a point that I liked is the work-life balance needs to ... because a lot of the traits don't actually have that problem. Like you were saying, it's not-

Andy:

Seven to three or you have to work around whenever the homeowners not home. Then they're home at ... sometimes there's even less than that. You have from nine to three to do this job and then, if the parents come home from work and school and shit, then you got to go. So then you're done for the day. But I don't know, there definitely could be something done with a four-day work week thing though. I wish that would be more standard across the board. I've started to see a couple places start to offer it, do straight four tens, but it's definitely still very uncommon.

Speaker 2:

I have fought that at every single shop I have worked at. I have fought for that. One of the shops was really close to doing it. He was sitting down. We had 20 mechanics and he was sitting down, he was like, "Yeah, I think we can make this work. We can have four tens. We can rotate as long as there's some people that are good with doing this and some people that are good with doing that." For the most part we did, except for we had two mechanics that were like, "I'm not doing that. I'm going to work my normal five-day week and that's it." I'm like, are you stupid? Quit trying to ruin this for the rest of us. Why-

Andy:

They should've just let him work. That's the thing. Why do need-

Speaker 2:

That's what I said. Just let them do it.

Andy:

If you don't want to do four tens, go enjoy your five days.

Speaker 2:

Exactly. Exactly. Yeah. I'm going to have my three-day weekend. You can be satisfied with your two-day weekend if you want, but don't fuck it up for me, right?

Andy:

Think about how shitty Mondays would be though, having a three-day weekend every weekend.

Speaker 2:

I think it would be great, but I don't really party.

Andy:

After a three-day weekend ... no, not even that. Just I don't know. Monday's always-

Speaker 2:

It doesn't matter. It doesn't matter what you do. Mondays going to suck. It does not matter. It's Monday. Fun question that I love to ask everybody, mechanics at least on this, is what is your favorite fuck up and what is the your biggest accomplishment?

Andy:

Favorite fuck up.

Speaker 2:

We all have them.

Andy:

I guess I forgot to put oil back in a truck that I did an oil change on and I'm looking at the oil pressure gauge waiting for it to pop up, waiting for it to pop up, still at zero. I'm like, oh fuck. After a couple seconds, you finally realized. You're like, oh I fucked up.

Speaker 2:

Yeah, it clicks.

Andy:

Yeah, you're like shit. So I guess that was a pretty good ... that could have been a really bad up fuck up. Luckily I caught it in time.

Speaker 2:

It's just any of those moments where you're like, oh my God, I'm an idiot. Cause as mechanic, we've all had those where you do something, you're like, wow.

Andy:

Misdiagnose something and you're like ... then it just finally all clicks. Once you already did the misdiagnose, you're like, why did I even think about that? I don't know it. But maybe accomplishment wise, I'd like to say that I've never ... In four years, I've had a truck towed twice. So out of 35 trucks on the road seven days a week, I've only had a truck towed twice.

Speaker 2:

That's pretty good. That's pretty good.

Andy:

Yeah. I've take a lot of pride in my fleet trying to make it look as great as I can and perform as great as I can. So unfortunately, I'm not blessed with all brand new equipment. So I'm taking care of trucks ranging from like 2011 all the way to 2022. It's a lot of work, but it's definitely rewarding.

Speaker 2:

I agree. I had a young lady on here, well, she's kind of like my mentor. She was actually the last episode I just aired. That's something that we talked about was quality of work and how important that is, and taking pride in what you do is important. I'm always the motherfucker that will spend an extra three hours on an engine job painting it, making it look pretty. So I think even if it's just a rebuild or honestly, let's be honest, most of them are long blocks nowadays, not rebuilds. Even if whatever the case may be, the customer is getting a long block, short block, rebuild complete engine, which is usually painted, but whatever. Same concept. Make it look like they spent that money. They're spending well over $20,000. Make it look like they're spent over $20,000. It's always been a big thing to me is, if I had my engine rebuilt, even though it's an ancient pickup truck, if I took it to Cummins and I had them rebuilt it, I'd expect that motherfucker to be beautiful.

Andy:

Unfortunately Cummins Red was on back order for ... or it's called Apex Red that was on back order for a very long time and I just got a can of it two days ago. So I just did a long block in one of our trucks. Like you said, you want to paint everything, make it look nice, and I couldn't even get the paint to make it look nice.

Speaker 2:

That's maddening. I hate putting shit on. I'll paint water pumps. Some of John Deere's water pumps come black instead of green or yellow because it could be from both. So they just send it black and then I cannot stand people that bullshit on like that and don't paint it. Or vibration dampers, water pumps, anything. I have to paint it. I have an OCD thing and I have to paint it. It's got to be green or yellow. It's got to match. It might be the only shiny thing on that engine, but it's going to be at least yellow. I'm anal about stuff like that. It's got to be painted. It's got to be pretty. So take pride in your work. Your boss and your customers will appreciate it.

Andy:

But a little bit of paint goes a long way.

Speaker 2:

Exactly. It's cheap too. It's a cheap thing to do that makes it look so much better. But I've never understood why people don't paint their stuff.

Andy:

Another thing, you're talking quality work. Why wipe your greasy fingerprints off the side of a truck?

Speaker 2:

Yes. Yep. I am guilty of that. I am guilty of that. Yep. Well yeah, I've sat with a power washer with a piece of equipment for an hour trying to spray nasty greasy oil. Black diesel oil that's been not changed in the right amount of time, so it's like stains, that is such a pain in the ass to get off of everything.

Andy:

Especially if the paint has a little bit of fade to it so it doesn't have the clear to protect it [inaudible 00:41:43]. No good.

Speaker 2:

That is part of the reason why I liked equipment better than semis, because I worked on semis for a brief time and, at least equipment, it lives in the dirt. So if it is not perfect leaving that shop, no one's going to notice. So as far as dirt getting mud on the floor or whatever, which we usually detailed our equipment before it left anyways. But still, I remember a man that brought his Lone Star International into the shop one time when I worked on semis and that motherfucker had hardwood flooring in a semi. I'm like, okay, this is not my area of expertise. This is not a great fit.

Andy:

It does look pretty good though. I have a couple of ... two of our trucks have that. I used linoleum floor, like the interlock wood boards from Home Depot and took the seats out and just lined the floor with it. Ends up looking pretty cool.

Speaker 2:

If there's something I got to take my shoes off to work on, it's probably not something Melissa should be touching.

Andy:

So you got two pairs of shoes. You got outside shoes and you got inside shoes. People drive with slippers on, but then they wear work boots outside. I don't know.

Speaker 2:

That is ridiculous. More power to him for having a nice truck I guess. But Jesus Christ, it's a truck. That's why I am in equipment. You get to dig holes and fuck shit up and you have a work pile that you can just dig holes in and attempt to run a grater, which ends up looking more like a Motocross track when you're done with it than a fine grading job. But it's fun. I cannot grade for shit. Well, I can. if I can use the float function, I'm golden. I mean, not golden. It still kind of looks like shit, but it's better than ... If I got to sit there and actually run the controls, it's going to look like a Motocross track.

Andy:

Bouncing all over the place. You'll get more jobs doing truck suspensions after that.

Speaker 2:

Yep, yep. Now dozers and excavators, I can run the shit out of those because dozers, you just put the blade in and you just push shit around ,and excavators, you just dig a giant hole and then you fill it back in. I got that shit. Excavators especially, I can run the fuck out of an excavator. Graders on the other hand are a little bit of challenge. I like machines that you can put on full RPM and run it like that. I don't like loaders. I don't like running loaders with a gas pedal because you bounce around and it bounces a gas pedal and it's just annoying, and obviously it's not idled up all the way. So if you scoop a big giant bucket of dirt and you're trying to lift it up or you're trying to scoop dirt, you have to sit there and push the clutch disconnect and then rev it up and then move the bucket at the same time. That is way too much shit going on at once for me. So I just like excavators so I can just turn it up all the way and run it like that.

All right. It's fun. It's really fun, especially when you figure out how to do the zero turn where you can put the bucket on the ground and pick up one side and then you can do this fancy spin thing. Makes you feel like a badass. Yeah, it's really easy, but it makes you feel like a badass, and everybody that has no idea what you're doing thinks you're cool. So that's cool.

Leave a comment